Who Are We?

Over 20 years of experience focused on gas treatment

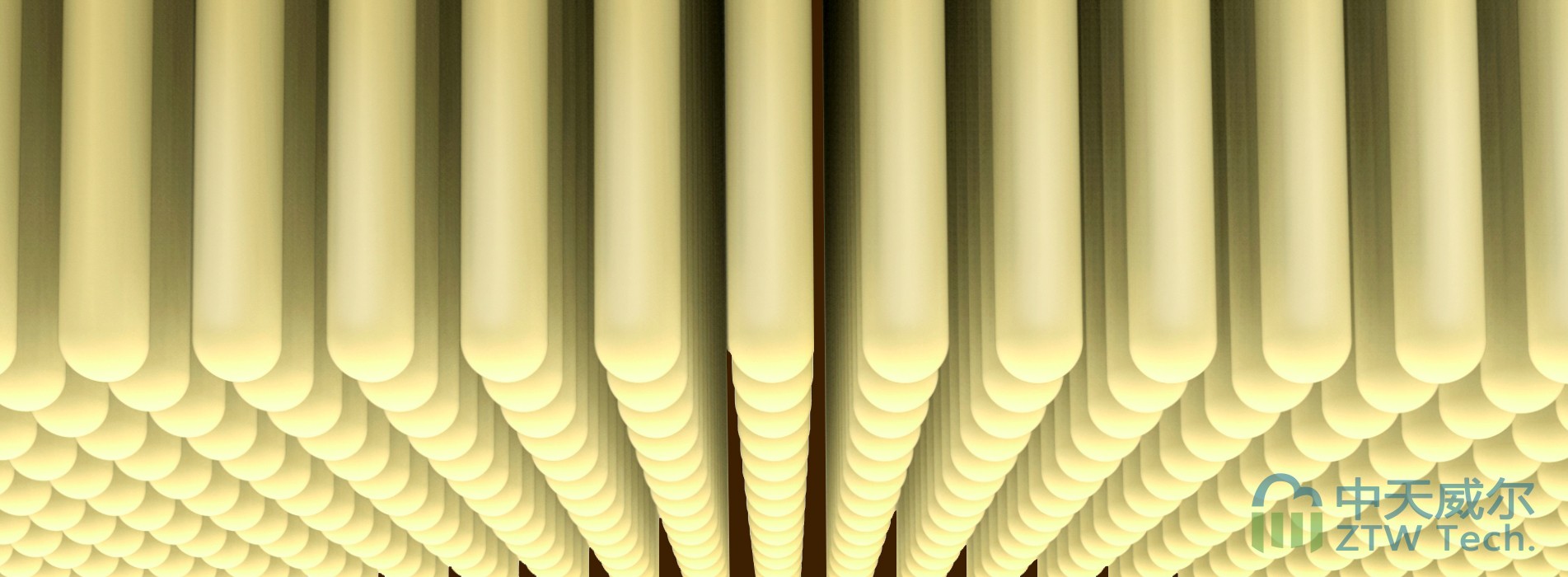

Experience in full-link engineering for industrial kilns, including low-nitrogen and full-nitrogen combustion systems at the source end, the rear environmental protection system, and waste heat recovery from flue gas at the tail end.

Solutions not just Products

Energy saving, emission reduction and carbon reduction

Integrate industry standards and on-site experience; based on big data and artificial intelligence platforms, the entire industrial process of industrial kilns that save energy at the source, emission reduction at the back end, and recycling at the end, and the entire life cycle operation and maintenance of unified standardized design, process operation and maintenance, and standardized operations are automated, intelligent and refined.